SL-PREDMNT-S2C

- Reference Design

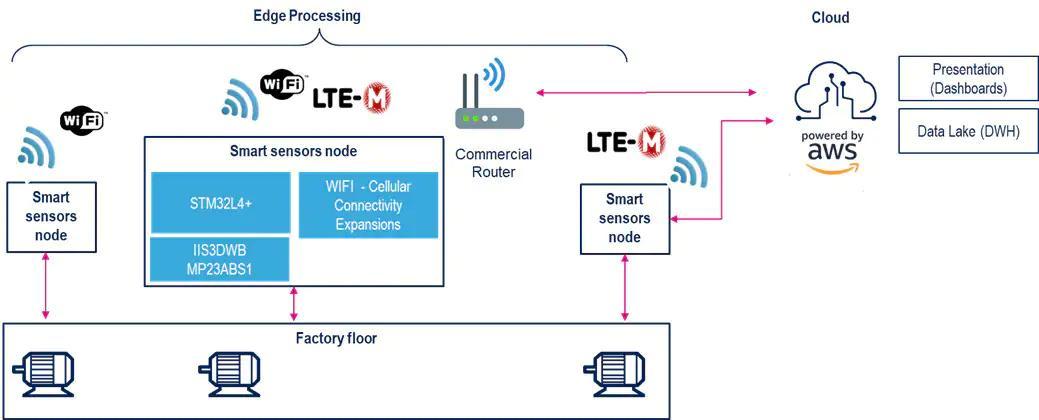

Vibration, ultrasound and environmental sensor nodes for condition monitoring with Wi-Fi and cellular connectivity to cloud applications

In the framework of Predictive Maintenance, Condition Monitoring plays an important role towards a Smart Factory and Industry 4.0 strategy where vibration, ultrasound and environmental data are collected by smart sensor nodes and shared for analysis in a central data lake or cloud services via Wi-Fi or cellular network connectivity.

Critical vibration data is processed locally on a high-performance, ultra-low-power STM32L4+ microcontroller by combining 3-axis acceleration data from a 6 kHz IIS3DWB vibration sensor and ultrasound data up to 80 kHz from a IMP23ABS1 microphone sensor to generate frequency and time domain analyses such as fast Fourier transform (FFT), root mean square (RMS), and peak acceleration. Environmental pressure, temperature and humidity data is also collected by the LPS22HB and HTS221 sensors embedded on the node.

The very-low power requirements of the MCU and the sensors allow for compact, battery-operated nodes driven by the STBC02 battery charger.

The STM32L4+ microcontroller supports wireless data transmission through an additional Wi-Fi module such as the Inventek ISM43362.

| Manufacturer | Categories | Application |

|---|---|---|

STMicroelectronics |

Test & Measurement | Measurement and Monitoring |