Videos

RLC Electronic Systems Inc. makes cutting-edge projects a reality

Phoenix Contact

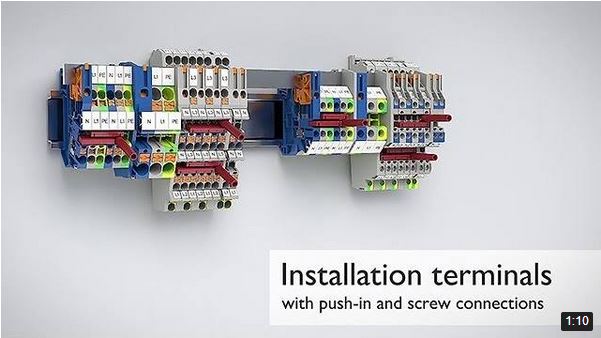

RLC Electronic Systems, Inc., located in Sinking Spring, PA, designs and manufactures custom electronic systems, updates existing products, builds to print, and creates completely new products for their clients. RLC can take your project from concept through planning, design, and engineering to produce a finished solution, ready to market. RLC leverages Phoenix Contact terminal blocks and connectors for their high quality and reliability.

Products mentioned:

Terminal blocks: https://www.phoenixcontact.com/en-us/...

Connectivity: https://www.phoenixcontact.com/en-us/...

Connectors for device connection and field cabling: https://www.phoenixcontact.com/en-us/...

PCB terminal blocks and PCB connectors: https://www.phoenixcontact.com/en-us/...

Related videos:

• BLUEMARK UV Printer for Terminal Bloc...

• Device Control Connectors

• The Top 5 Things to Know about Termin...

• PCB terminal blocks save time and mon...

• Mini PCB Terminal Blocks and PCB Conn...

Connect with us on social media!

Twitter: / phoenixcontact

Facebook: / phoenixcontactusa

LinkedIn: / phoenix-contact-usa

Subscribe for the latest on smart industry technology in IIoT, Industrie 4.0, power, automation, controlling, manufacturing, connectivity, and protection. We bring information, how-to’s, tutorials, and case studies on machine learning, industrial internet, technology, software, STEM, and more!

Subscribe: https://www.youtube.com/user/PhoenixC...

Transcript:

- My name is Zach Martin. I am the Director of Engineering at RLC Electronic Systems. RLC Electronic Systems is a design and manufacture company. We do OEM builds for a variety of companies They bring us a product idea and we'll come up with some sort of solution. We'll do embedded software, we'll do electronic controls, all sorts of stuff, box builds, whatever they want, and we'll propose a solution to them and manufacture it here in-house. We've worked in things like cryogenic materials handling, water sterilization. We've worked for cruise companies, doing like infotainment type stuff, gaming companies, really, you name it, anybody that has an embedded device that they want to control something, they want to move something, they can come to us and have a solution. We've had a longstanding relationship with a water sterilizer company. We've built multiple different controllers for them to handle different applications for water treatment, and they came to us and they wanted a new device. They wanted to make it a little simpler to install. They wanted to go with like a easier, tool-less way of doing it. So we looked into lever-style terminal blocks and got in touch with Phoenix Contact, tried a couple of different ideas out, and ultimately we stuck with the, I think it's the LPTA Lever Blocks. They like that they could come in from, basically, a 45 right into the board. They felt like it was easily accessible. They could either do a stab in, cause some of their connectors and some of their wires are solid. They could also pull the lever back and put in some stranded wire without having to worry about ferrules or crimping or anything like that. So they did really like it. Our relationship with Phoenix Contact, I feel like it's a reciprocal relationship. We have product that we want to find a solution for, our customer wants a solution for, and we reach out to them, we say, ""Hey, what do you guys have in this line?"" And we do the best. We work with Ben, we do the best we can to find something that, ""Hey, is it going to be a fit? Is it not going to be a fit?"" If it is, like in this case, it's a winner, then, ""Hey, we got sales for you guys."" If it's not, then we just move on to the next thing. So our relationship, I feel like if I have a connector issue, connector question, I just kind of have an informal, like, ""Hey, let's talk about this application. This is where it's going."" And Ben comes back with possible solutions. (continued) --