~Manufacturer Interview~

Where you can read interviews with those in charge of development sites

and product planning talking about their strategies and directions for the future,

focusing on manufacturer hot topics and products they are currently focused on the most.

※Monthly updates of the latest industry trends

The relay market is expanding with the advancement of smart major appliances, and TE aims for No. 1 in shares through reliability and price competitiveness

Mr. Leo Wang

In home appliances and industrial equipment applications, a relay is used to connect the input and output. An electric current is passed through the coil and the mechanical contact is switched ON/OFF by the generated magnetic field. Which is why there are cases where they are called mechanical relays, reed relay, and power relays.

The history of relays is long, with its principle invented in 1835. Even now, around 185 years later, the importance of its role remains high. The importance is on the rise in particular for home appliances, industrial equipment and lighting equipment. The market is also expanding. By 2022, the market for home appliance relays is expected to reach US$ 1.2 billion worldwide.

TE Connectivity is one of the leading manufacturers of the major appliance relay market. Currently, they have secured second place in the world’s largest market shares (according to TE Connectivity). However, they are not satisfied with this current situation. They are aiming for the “World No. 1” spot by increasing their market shares.

In this interview, we asked Mr. Leo Wang, Product Management’s Global Product Manager for TE Connectivity’s Appliance Business Unit, about market trends surrounding relays for major appliances, business strategies for acquiring the world’s top position, and details about the latest products.

(Interviewer: Katsumi Yamashita = technical journalist)

What is the current status of relays for major appliances.

Wang: In the major appliance market, relays are still positioned as important parts. In fact, the market for major appliance relays is expanding. The global market size was US$ 1,000,006,600 in 2017 and is expected to grow to US$ 1.2 billion in 2022. The Compound Annual Growth Rate (CAGR) over these five years will reach 2.4%. You can say that extremely stable growth can be expected in this market.

Why is the major appliance relays market growing? Can you explain the factors.

Wang: The biggest growth factor is the application of “Smart Connected Technology” in air conditioners and refrigerators. The smart connected technology is, for example, having a wireless LAN (Wi-Fi) function. These days, it’s not rare for home appliances to have wireless LAN function. If you use a wireless LAN function, you can operate your home air conditioner with your smartphone from outside and keep it at a comfortable temperature for when you get home. The “smartness” of home appliances will be greatly enhanced.

The more home appliances become smarter, the more complicated their internal structure becomes. For example, while conventional appliances use only one relay, smart appliances will use two or three relays.

Furthermore, we cannot overlook the influence of making home appliances high-end. The number of single-function home appliances that were used in the past has decreased and multifunctional “high-end appliances” equipped with various functions are increasing worldwide. With making home appliances multifunctional, like with smart appliances, it will cause internal configuration to become more complicated and result in an increase in the number of relays mounted. These circumstances will be the driving force for the home appliance relay market to expand.

Achieving a growth rate greater than the industry average

How is the home appliance relay business doing currently at TE Connectivity?

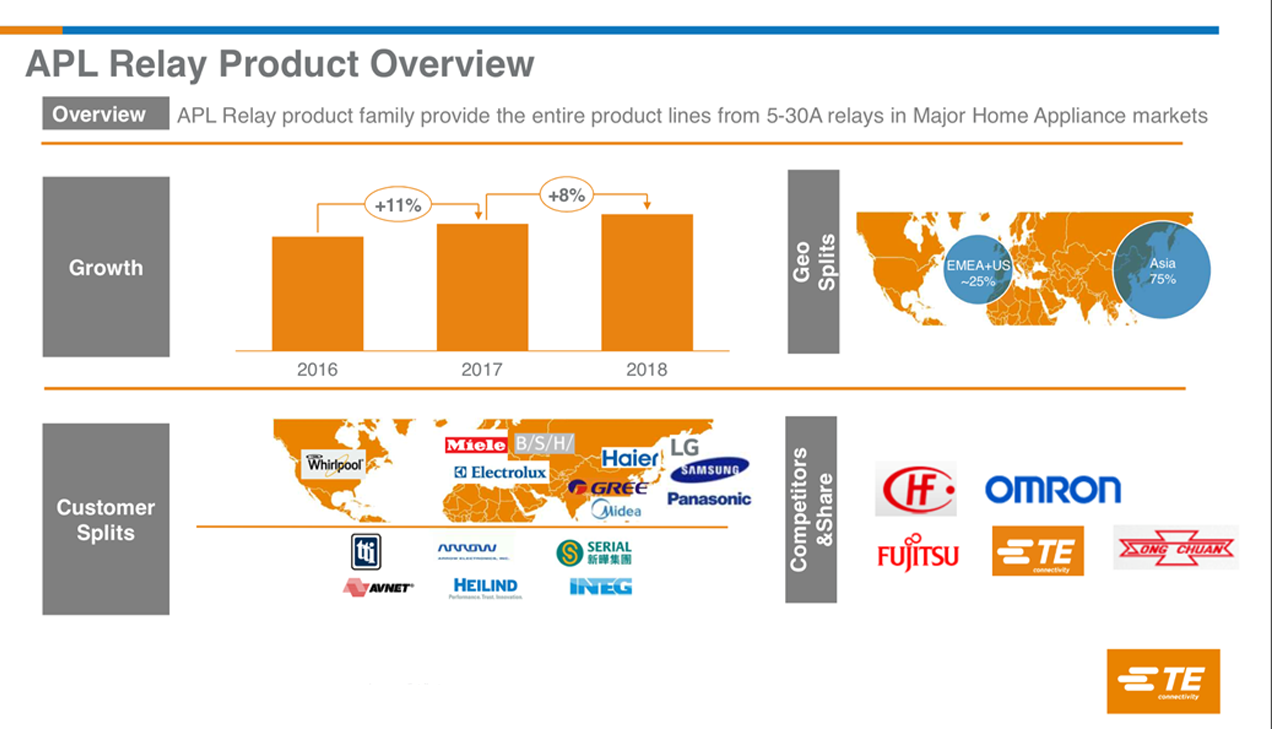

Figure 1: Current state of the home appliance relay business

The home appliance relay business of TE Connectivity is growing steadily. Sales have increased in 2017 by 11%, and 8% in 2018 year-on-year.

Wang: It’s doing very well. Sales in 2017 achieved an 11% increase compared to the previous year and an 8% increase in 2018.

Tell us the sales by region.

Wang: Looking by region, the percentage of sales held by Asia is a very high 75%. On the other hand, the percentage for United States and Europe is only 25%. However, we are focusing on sales activities in the United States and Europe, and Japan.

Who is your competitor.

Wang: Our biggest competitor is China’s Xiamen Hongfa Electroacoustic, who is No1 in market shares for mechanical relays. Hongfa has a very broad product lineup and sells to a wide range of markets worldwide. They also have a high price competitiveness. Which is why they have gained a large market share.

Japanese manufacturers such as Fujitsu Component, Omron and Panasonic can also be listed as rivals. However, Japanese manufacturers are not very strong in the home appliances market because they tend to specialize in industrial applications. And, although the company has made significant sales in the Asian market, it has relatively low competitiveness in the European market. So, their market shares are lower than Hongfa and TE Connectivity.

Another that can be added to the list of competitors is China’s Song Chuan Precision. In other words, we can say that TE Connectivity, Omron, Fujitsu Component, Panasonic and Song Chuan form “Tier 2”

Speeding up the automation of the production line

What is TE Connectivity’s target for major appliances in relays?

Wang: To become a top supplier or top manufacturer in the global market of home appliance relays (Figure 2).

We believe there are four essential points to achieve this goal. One is to ensure extremely high quality. For that, we are actively pursuing the automation of production lines (Figure 3). By pursuing in automation, we can significantly reduce the number of defective products cause by human error and the deterioration in quality. As a result, it is possible to have stable manufacturing of very high-quality relays. The second is to improve price competitiveness. The automation of production lines also contributes significantly to price competitiveness. In a production line that relies on a manual (human hands) process, the higher the labor costs, the higher the price for the product, and the lower the price competitiveness. However, if the production line is automated, the impact of labor costs will be very small, and products can be produced at a fixed price.

The third is to establish a global sales/sales system. TE Connectivity has already set up sales/sales offices around the world for key customers. In the future, we would like to work on improving sales and service capabilities of these offices. The fourth is to provide comprehensive solutions. We have gained a high market share in connectors and are among the few manufacturers that can supply connectors and relays to home appliance manufacturers. Together, the connectors and relays can provide a complete solution. From the customer’s point of view, one-stop-shopping is made possible. We believe this merit to be very large.

What are the points of particular concern or focus in services for users in Japan?

Wang: The demands of Japan users are more stringent than those of other Asian users. Which is why we aim for short lead times and quick responses to questions.

In this regard, we are working to meet the needs of Japanese users with the cooperation of our business partner, the electronic component trading company. In the Japanese market, electronic component trading companies play a major role. That’s because 50% of our business in the Japanese market is direct business where we sell directly, and the other 50 % is channel business where we sell through an electronic parts trading company. Which means, the proportion of channel business is relatively large. With the Asian market, on the other hand, direct business is a large 80% while channel business is a mere 20%

Contributing to the miniaturization of major appliances with the use of low-profile product

What kind of products are you currently putting on the market.

Figure 4: 6 product series are available

The “PSoC 4700”. The CPU core is equipped with “Cortex-M0+” by the English company Arm. Also, “CapSense” , a single-slope 10-bit analog-to-digital converter, two 7-bit current-output digital-to-analog converters, and comparator are integrated onto one chip.

Wang: We have six product series are available for the home appliance market (Figure 4). They are the 3-5A compatible “PCJ series”, the 3-10A compatible “OJ series”, the 5-10A compatible “PCH series”, the 15A compatible “OMIH series”, the 16A compatible “RZF series”, 20-25A compatible “PCF series”. These 6 series supports major home appliances like air conditioners, dishwashers, refrigerators, and washing machines, and small home appliances such as coffee makers, toasters and electric kettles.

In addition, they are also used in industrial equipment like power meters, lighting fixtures, and programmable logic controllers (PLC). Even with industrial equipment, reduced prices are required depending on the product. Therefore we are using relays for home appliances to lower prices.

Can you introduce your latest products?

Figure 5: The “RZF series” realizing low profile

The mounting height is only 27.6 mm. It has achieved the lowest mounting height in the industry for home appliance relays with a rated current of 16A.

Wang: I would like to introduce our new product series the “RZF series” (Figure 5). With a voltage rating of AC250V, and a rated current of 16A. The contact configuration is “1 Form A (single pole single throw)”. The RZF series has multiple benefits for users.

The first is that the actual height is a mere 27.6 mm. It achieves a 20% reduction in height compared to competitors with a rated current of 16A and is the industry’s lowest level in mounting height. There is a strong demand for low profile in relays. The relay is the tallest of the components mounted on the printed circuit board. So, if a low profile can be realized, miniaturization of home appliances and the like becomes possible.

The second is that they are completely manufactured on an automated line. There is absolutely no manual production process. Therefore, it is highly reliable and cost competitive. The third is the acquisition of various international safety standard. For example, UL and VDE and acquired safety standards such as CQC. So, they can be used for global home appliances that are sold all over the world.

Specifically, how can it be used with major appliances?

Wang: The main applications are microwave ovens, vending machines, water heaters and ovens. Also, because the rated current is relatively large at 16A, it may be compatible to industrial equipment. We hope to also actively market it for industrial equipment.

Click here to purchase TE Connectivity’s space-saving RZF relays

Power PCB relay with top mounted quick connect tabs for load connection

RZF relays are lower in height than other similar relays with a rate up to 16A and are suitable for microwave ovens, water heaters, electric cooking ranges, vending machines, and other industrial/commercial applications.

TE Connectivity (TE) is a world leader in relay manufacturing, delivering consistent high quality, innovative relay products and system solutions.

In addition to the new products introduced here, we introduce the wide range of PCB Power Relays!