~Maker Interview~

A place for people to talk to those in charge of development and product planning regarding strategies

and future policies, focusing on manufacturer HOT topics and current most focused products.

※Delivering the latest industry trends every month.

Heat shrink tubing essential for protection of wires, etc.,

with a focus on technically demanding HARSH environments

Richard Kewell

You may have seen black, green or transparent tubes wrapped around various wires. This kind of wrap or tubing is commonly referred to as "Heat Shrink Tubing". A tube is placed around the wire, and when it is heated, it shrinks and adheres to the wire. This allows the wires to be electrically insulated and protected from mechanical forces, chemicals and water droplets. You can also make use of colorful tubes to identify cables and enhance aesthetics. While it's not "flashy", it is an essential product for electronic devices, automobiles and aircraft.

Currently, TE Connectivity holds market share of approximately 65% in the global heat shrinkable tube market (TE survey). The heat shrinkable tube business was originally handled by Raychem. Raychem was acquired by TE Connectivity in 1999, and has continued to operate since then. The source of its high market share is its technical and sales capabilities cultivated through years of experience in the market. We asked the product manager for heat shrink tubing, Mr. Richard Kewell, about the role of heat shrink tubing, the main market, product features, product lineup, etc.

(Interviewer: Katsumi Yamashita = technology journalist)

What are the characteristics of the heat shrink tubing that TE Connectivity is commercializing?

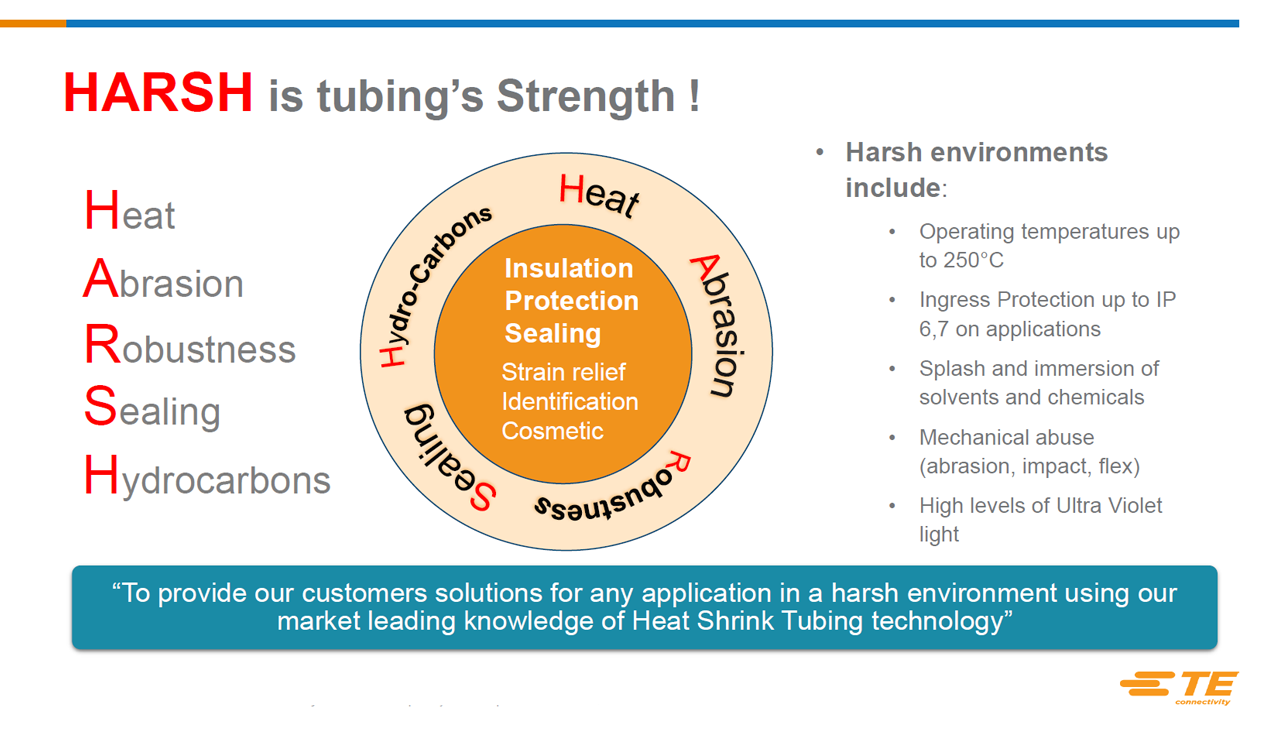

Kewell The company's vision for the heat shrink tubing business is to provide solutions for applications used in HARSH environments. This is of utmost importance.

What exactly is a harsh environment?

Kewell The word "HARSH" can be decomposed into "Heat", "Abrasion", "Robust", "Sealing" and "Hydrocarbon". That is, environments that require exposure to high temperatures, friction, ruggedness, waterproofing, and protection from hydrocarbons (hazardous substances). Common electronic components alone are insufficient to protect applications from such environments. The role of the heat-shrinkable tube is to complement it.

What are they actually used for?

Kewell The applications of heat-shrinkable tubing can be broadly classified into seven categories (Fig. 1). The first is "insulation." This is achieved by covering electronic components such as wires and terminals. The second is "strain relief". Used to protect the terminals from the load caused by pulling on the wires when disconnecting the connector. The third is "protection". Protect the inside of the application from friction, impact, ultraviolet rays, chemical substances, etc. The fourth is "sealing". Protect the inside of the application from water, moisture, oil, etc.

The fifth is "cosmetics". The purpose is to enhance aesthetics. The sixth is "identification". For example, cover the ground wire with green or green/yellow heat shrink tubing to make it easier to distinguish from other wires. The seventh is "shielding". The purpose is to shield from electromagnetic waves. This is done by combining metal foil with heat shrink tubing.

Please tell us specifically about the main applications of heat shrinkable tubing.

Figure 2: Automobile engines use multiple heat shrink tubes

It is used to protect wires, connect wires (splices), protect ring terminals, protect connectors, and protect pipes.

Kewell Heat shrink tubing is used in all kinds of industries. From an application point of view, it can be said that it is a borderless product. In other words, the application does not depend on a specific industry, giving it endless sales opportunities.

Let's look at some specific application examples. Currently, in the home appliance field, we are focusing on small appliances that are used outdoors. For example, use on a lawn mower to protect from water/moisture and vibration. In industrial equipment, it is often used for protection from ultraviolet rays and high temperatures. It is also used for various purposes in automobiles (Fig. 2).

In addition, it is used in aerospace applications such as satellites. In a vacuum like environment, a phenomenon occurs in which low-molecular-weight materials are released from high-molecular materials (outgassing). Heat-shrink tubing is used to protect electronic devices from this phenomenon.

The Japanese market share is not yet high, but it is expanding, and doing so with high product appeal

What are TE Connectivity's strengths in the heat shrink tubing business?

Kewell High responsiveness. We have technologies and products that can satisfy any user issue and any application request. This is our greatest strength.

It is true that our products are not the cheapest compared to our competitors' products. However, we have continued the heat shrinkable tube business for more than 50 years and have accumulated priceless knowledge and technologies. Furthermore, in 1999, we acquired Raychem, a manufacturer specializing in heat-shrinkable tubing, and inherited the brand name. Knowledge, technology, and brand power. Taking advantage of these, if there is a new problem or demand from the user, we will continue to develop products for it.

What is the current market share of heat shrink tubing? And who are your competitors?

Kewell Our global market share is approximately 65%. Raychem was the first company in the world to commercialize heat-shrinkable tubing. We took over that business in 1999 and have continued to do so, resulting in a high market share. We believe that moving forward, we will continue to expand our market share.

Competitors include Sumitomo Electric Industries in the US and Asian markets. The company's products are known by the name of "Sumitube". For the European market, it would be German company DSG-CANUSA. In addition, LG of South Korea and 3M of the United States are also competitors, but these companies tend to develop products that prioritize price rather than products for the HARSH environment. Therefore, the market we focus on is different from theirs.

What is your market share in Japan?

Kewell To be honest, the domestic market is in a very difficult competitive situation. This is because when Raychem was operating in Japan, it had a policy of only selling products for aerospace and defense applications. In the meantime, Sumitomo Electric Industries expanded sales of Sumitube and acquired a large share of the market. After that, we acquired Raychem. Since our company also had AMP under our umbrella, we quickly recovered our market share by selling heat-shrinkable tubes together with connectors and believe that the company's market share in Japan is steadily increasing at this point.

Two structure types available

I would like to understand more about the lineup of heat shrink tubing.

Figure 3: Two heat shrink tubing structures

There are single-layer tubes and double-layer tubes. A single-layer tube consists only of a sleeve / jacket, while a double-layer tube contains hot-melt adhesive.

Kewell Heat-shrink tubing can be broadly divided into two types according to their structure (Fig. 3). One is Single Wall Tubing, and the other is Dual Wall Tubing.

The single layer tube is a structure used in general products and is not waterproof. There are three types of materials used: polyolefins, fluoropolymers, and special halogen-free materials. Polyolefins are used in products that operate at common temperatures, fluoropolymers are intended for high temperature applications and special halogen-free materials are used in products for applications that require compliance with halogen regulations, such as railroads and marines.

The two-layer structure tube contains a material called a hot-melt adhesive inside. It acts as an adhesive that melts when heat is applied. When heat is applied, it shrinks, and at the same time the hot-melt adhesive melts and covers the wire. As a result, it physically prevents water and humidity from entering, and leaves the wire completely drip and water proof.

So, what kind of products do you have for single-layer tubes?

Kewell Fig. 4 is a map showing the lineup of single-layer tubes. The English names in the map are the names of the product series, and the description below is the operating temperature range.

In order to respond to user requests and application trends, we have prepared multiple products made by changing the materials used and blending ratio of materials. The numbers "4:1 (4 to 1)" and "3:1 (3 to 1)" in the map are shrinkage ratios. The greater the shrinkage ratio, the greater the shrinkage when heat is applied, providing a better fit with wires.

Among single-layer tubes, "CGPT" is positioned as a standard product series in the global market. Based on this, we have prepared a series of products with various added values. For example, the British standard is "RNF-100". In the Japanese and Asian markets, compliance with the flame retardant standard "UL VW1" for cables is essential, so "VERSAFIT" is selling a lot. In addition, "RNF-3000" and "RP4800" were developed for users who require a high shrinkage ratio. "RT-375", "RW-175", and "HT-200" have expanded the operating temperature range.

Please tell us about the lineup of double-layered tubes.

Kewell A map showing the product lineup of double-layered tubes is shown in Fig. 5. The most general product series of double-layered tubes is ATUM. This product series is first introduced to users who want a double-layer structure tube. In Japan, it is widely used in industrial equipment.

There are two things to keep in mind when choosing a double layer tube. One is that waterproof products have a lower operating temperature range. Normally, it is +80°C or +110°C, and even the highest product is +150°C of "SCT". The other is that if you don't choose the right product, you won't get the waterproof performance you need. Therefore, we would like you to communicate with our engineers and sales representatives and select the product that is right for you.

Used in F1 cars

Are there any other products you would like to tell us about?

Kewell We also have a line of products that we call 'specials'. The map is shown in Figure 6. Based on the general product series of single-layered and double-layered tubes, we have added extra functions to meet the needs of users.

For example, "TC CAPS" or "ES CAPS" is a product series that has been made to close one end of a two-layer structure tube. Literally, it's shaped like a cap. The demand for this in the automotive industry is very high. "RAYRIM" is a product series for metal edge processing. There is always a risk of injury if the operator's hand touches the edge of the metal. Therefore, this product is placed over the edge and heat is applied. It then shrinks, creating a cushion that protects the operator from the metal ends. This product series uses a V-shaped structure, which makes it easy to cover metal ends.

The "HFT5000" is characterized by its manufacturing method. A typical heat shrink tube is manufactured by injection molding. However, the HFT5000 is manufactured by knitting two strands of material. Weft yarns have shrinking property and warp yarns do not. When heat is applied, it shrinks. Used for protection against any kind of external forces. For example, it is used to protect the pipe attached to the bottom of an F1 car from contact with the road surface.

There are many product series available, but what kind of process do you need to go through when actually choosing the most suitable product?

Kewell There are three stages in the process of selecting a product. The first step is to determine the optimal heat shrink tube product series name based on the environment and temperature in which it will be used. The second step is to determine the application. Picking the right size is important. It can't be tight, it can't be loose and the thickness is also important. If it's too thick, it takes up too much space, if it's too thin, it might not be able to do its job as expected.

The third step is to decide on the colors and complete the delivery form. In Japan, black tubes are the most popular. However, transparent products are often used for double-layered tubes. Green or Yellow should be chosen for ground lines. Finally, the type of package and type of delivery can be decided on. Packages types available are stick, spool and flat spool.

Expected to continue to grow at an average annual rate of 4-5%

What tools do you use to heat the heat shrink tubing?

Kewell Use a hot air gun to process small amounts of heat shrink tubing. Like using a big hair dryer. However, when processing a large amount of heat shrinkable tubing, the hot air gun can causes problems such as an instability with regards to quality. Therefore, we have other equipment such as belt heaters and tunnel ovens for mass production (Fig. 7). With this kind of equipment, we can maintain an environment that allows stable processing of heat-shrinkable tubing.

How do you see the heat-shrinkable tube market going forward?

Kewell The global spread of the new coronavirus has not yet subsided, and the future remains uncertain. However, the heat-shrinkable tube market is still expected to grow steadily in the future. We can expect an average annual growth rate of 4-5%.

Please tell us about your future product and sales strategy.

Kewell The core of our heat shrink tubing business is to focus on the HARSH environmental field. We focus on technically demanding markets, avoiding markets that are not very technically demanding and are at risk of falling into price competition.

The core never wavers. In addition to this core, we have two strategies. One is to actively utilize partnerships with distributors. While the performance and quality of our products are at an all time high, we recognize that the delay in developing sales channels is an issue. There are still a lot of users who have not experienced our product and we would like to reach out to such companies by utilizing partnerships with trading companies. Asian markets such as Japan and China rely on Chip One Stop.

The other is to actively work on the development of new products. Expanding sales channels through partnerships with distributors will bring in more user and market information. In addition, user needs should become clearer. For example, as with electric vehicles (EVs), when new applications and technologies appear, the key is to get in and understand quickly. To that end, it will be important to develop new products that meet customer needs as quickly as possible.

Our company has many years of experience. Combining partnerships with distributors and new product development, it is inevitable we will gain a leadership position in the heat shrink tubing market.

Introduction of specialty stores

In addition to the above, we have a lineup of many TE products!

Take a look at the TE specialty stores!

TE manufacturer interview